The future of pharmaceuticals will not be written in batch sheets, but in bytes. For decades, the pharmaceutical supply chain has been the silent engine of global healthcare — dependable, precise, yet mostly invisible. But the world has changed. Disruptions, data explosions, and sustainability expectations have rewritten the playbook. It is time the industry moves from Supply Chain to Smart Chain — not as a slogan, but as a systemic redesign of how we make, move, and measure everything.

Traditional supply chains were built for efficiency. Smart chains are built for resilience, transparency, and foresight. The post-pandemic decade has revealed the fragility of global pharma networks — over-dependence on single-country intermediates, regulatory fragmentation, and rising carbon accountability. According to Deloitte, 85% of pharma leaders are investing in digital supply-chain capabilities, yet fewer than 20% report measurable ROI. Why? Because technology alone cannot fix what culture hasn’t embraced. Smart chains require a fusion of data, discipline, and decision-making courage.

The Forgotten Foundation: APIs and Excipients

When we talk about digital transformation in pharma, the conversation often drifts toward biopharma, formulations, or patient interfaces. But the foundation of the industry — the world of APIs and excipients — carries its own complex challenges and opportunities. Batch variability can influence entire process yields. CEP and USDMF filings now demand real-time traceability, not retrospective paperwork. Each molecule can travel through a dozen intermediates across continents before it becomes a finished dosage. In such a system, visibility is not a luxury; it’s a lifeline. Smart-chain thinking, therefore, must start at the reactor and raw-material level — where data integrity, automation, and predictive insights can redefine both quality and compliance. Every data point becomes a molecule of trust.

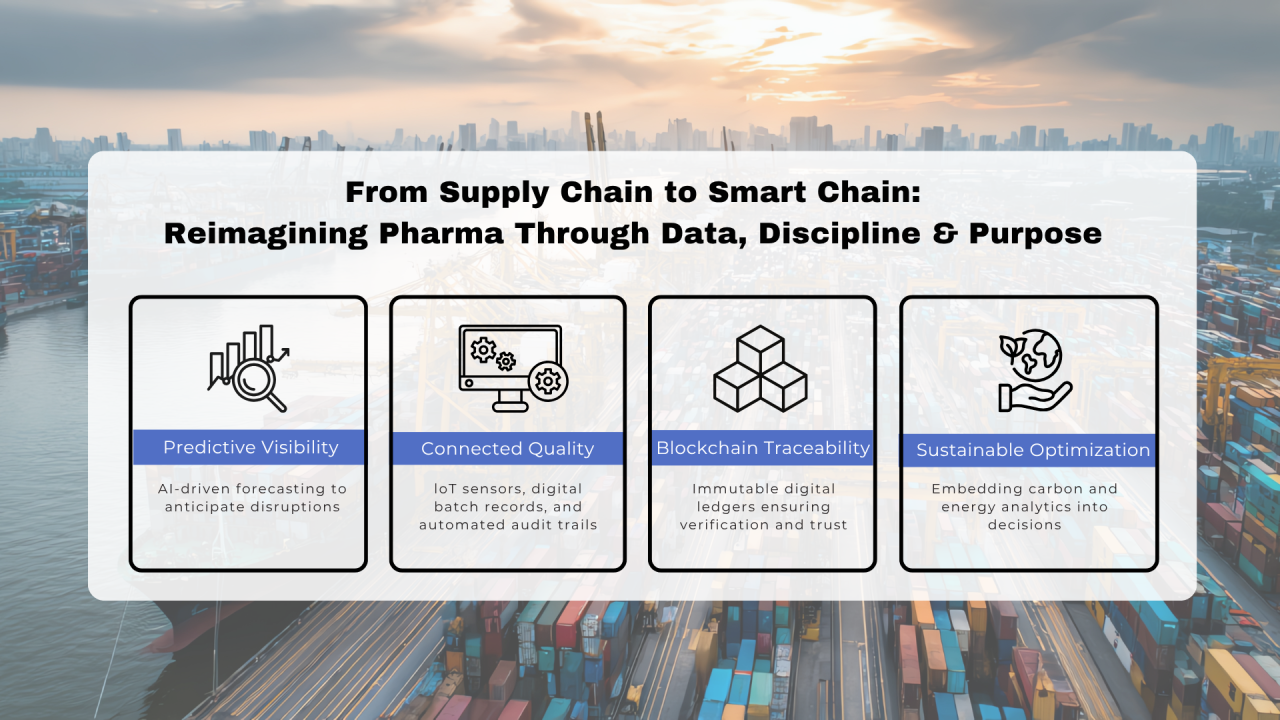

Four Levers Driving the Smart Chain Revolution

1. Predictive Visibility: AI and advanced analytics are enabling supply networks that can sense disruptions before they occur — from logistics delays to supplier risks. Scenario modeling and real-time dashboards are replacing manual coordination with proactive foresight.

2. Connected Quality: IoT sensors, electronic batch records, and live audit trails transform quality from a compliance checkpoint into a continuous assurance model. Deviations are identified and addressed in real time — creating a “self-healing” system.

3. Blockchain Traceability: Immutable digital records allow every stakeholder — from manufacturer to regulator — to access a single version of truth. Blockchain doesn’t just enhance trust; it creates auditable transparency by design.

4. Sustainable Optimization: Smart chains must also be green chains. By embedding carbon and energy analytics into operations, decisions can balance efficiency with responsibility — optimizing for both cost and conscience. Digital doesn’t just make supply chains faster; it makes them future-ready.

The Human Equation: Technology Is the Easy Part

The success of any smart-chain transformation hinges less on algorithms and more on attitude. A digital twin is only as powerful as the conviction of the operator who feeds it. Every transformation effort that succeeds does so because of culture — the mindset to learn, adapt, and take ownership. Leadership must drive this shift by ensuring three essentials: • Digital literacy at every level — from chemists to planners. • Empowerment through insight — where teams are rewarded for intelligent action, not just output. • Encouragement of experimentation — because innovation often starts with permission to try. A Smart Chain is 30% technology and 70% culture. Without belief, there can be no breakthrough.

The Economics of Being Smart

True transformation is measurable. The success of a smart chain is reflected in four outcomes — Resilience (fewer disruptions and faster recovery), Quality (shorter deviation cycles and fewer defects), Sustainability (reduced carbon intensity per output), and Speed (faster technology transfers and product launches). In leading digitalized networks, these improvements have translated to up to 40% higher supply reliability, 30% shorter release times, and nearly 20% energy savings per batch. This is not just operational excellence; it’s strategic endurance.

The India Opportunity

India’s vision of becoming a $450-billion pharmaceutical ecosystem by 2047 depends not only on scale but on sophistication. We must evolve from “Make in India” to “Think in India.” Imagine an ecosystem where API clusters run on AI-based scheduling and energy optimization; DSIR-accredited R&D centres connect seamlessly to manufacturing via live data; and regulators access blockchain-backed documentation in minutes. This convergence of digital, discipline, and design thinking can make Indian pharma synonymous with trusted global innovation.

Leave a Reply